My Griff complete rebuild

(David Hammerton)

I

picked up my Griff in March 2004 from a guy in Essex, It’s a 94

Pre-serp 500 with T5 box, I got it for a good price with a leaking

radiator. I purchased a new rad from Peninsula and promptly

fitted, this solved the over heating problem and away I went a happy

bunny J

Due to working abroad I was only in

England for 2 weekends a month, this was agony knowing that my baby was

waiting in the garage at home for me. By July I’d decided I’d had

enough so I took my car out to Germany for a whole month J

Driving this car out there in great weather everyday for that month was

absolutely awesome, an experience I won’t forget and hope to repeat in

the near future. I put over 4000 miles on the car that month

without any problems, which proves how reliable these cars can be.

My car outside my apartment in Germany last year (2004)

I

continued to use the car every other weekend when I was home up until

Christmas. On January 5th 2005 I was reading a thread on

Pistonheads about body off chassis restores, knowing that mine had some

rust on the outriggers I was interested in the topic. By the end

of the thread I’d decided to undertake the task, on the 6th of Jan the

project started!! I had no intention of doing this until the day

before!

My plan was to ‘simply’ remove the body,

cleanup and paint the chassis and replace the body. Things don’t

always go to plan!

The process started with removing components from the engine bay so that the engine could be lifted out

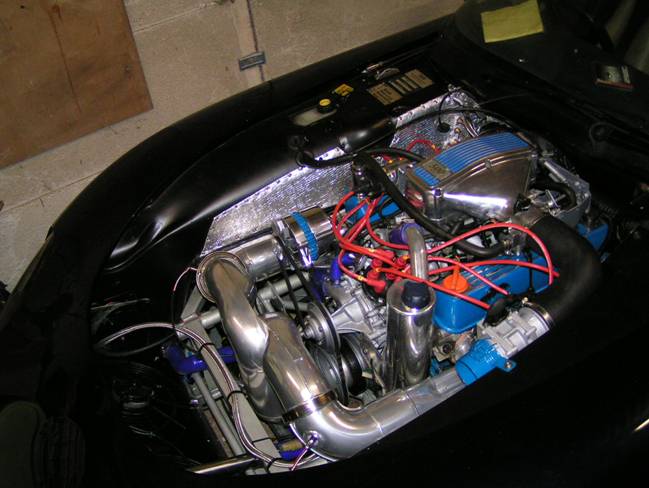

My engine before the strip started

I don’t seem to have any pictures of the engine just before I lifted it out, but here it is partially stripped.

After

disconnecting everything necessary (including the propshaft, exhaust

Y-piece and some other items) it was not too difficult to lift the

engine out, if a little tight (manifolds are a close fit to the

bay). The biggest problems I had were with detaching the engine

and gearbox mounts.

The engine was now out and sitting on my garage floor

Empty engine bay

I detached the gearbox from the engine and set these both aside for now (must have been pissed whilst taking this!)

My next step was to start stripping of all of the suspension components

It was a bit rusty under there

I then removed the drive shafts and the bolts holding the wishbones and continued to dismantle.

Under RH rear arch pic with the wishbones removed

LH shown below

Front right hand

Front hub with brakes

Rear hub with driveshaft and brakes

The wishbones were in a bit of a mess, lots of surface rust

Someone had already treated the front wishbones with what looked like Hammerite, but they made a bad job of it

A

couple of the front wishbone bushes were in a really bad way, the

rubber was no longer attached to the metal outer casing. The

inner (with rubber) could freely be moved away from the outer!

With

the wishbones now removed it was time to separate the body from the

chassis. Because I was going to be doing this alone I followed a

method used by Phil (AKA Wheeljack888 on Pistonheads) on his Chim

This method involves getting the body and chassis up high, the supporting the body and lowering the chassis down and out.

The

body is held on by 28 bolts in all; 2 near the radiator, 2 below the

dash, 4 behind the fuel tank, 14 underneath on the outriggers, and 6

for seatbelts. I also removed the radiator before the

engine. The brake lines were all disconnected from the right hand

side of the engine bay, speedo sensor wiring disconnected, fuel tank

removed (to access the chassis bolts behind it), fuel pump wiring

removed and probably a few other bits which I can’t remember right now!

The

chassis was wedged quite tightly in to the body and would actually hold

there under its own weight! But with a little persuasion it came

out (I wish it was as easy as writing this to actually do all this

stuff!)

The chassis looked quite bad in some areas

The underside of the body was in need of a clean as well

I

then removed the diff and realised now would be a good time to have it

and my gearbox reconditioned. After a bit of research I found

that ‘Competition Transmissions’ specialise in these units and were

more than happy to do the work for me

I

then stripped the chassis down to a bare frame and took the surface

rust of with my angle grinder using a knotted wire wheel and found that

it was indeed only surface rust and the integrity of the metal was

actually very good. It was good to find out that no welding was

necessary and that I’d caught the dreaded rust in the nick of time! J

I

continued cleaning the chassis up with my trusty knotted wire wheel

(gone through 3 by now!) but came to the conclusion that I was getting

nowhere fast and also the surface was way to smooth for paint to key

to. So I sent the chassis away (and the wishbones and anti roll

bars) for shot blasting J

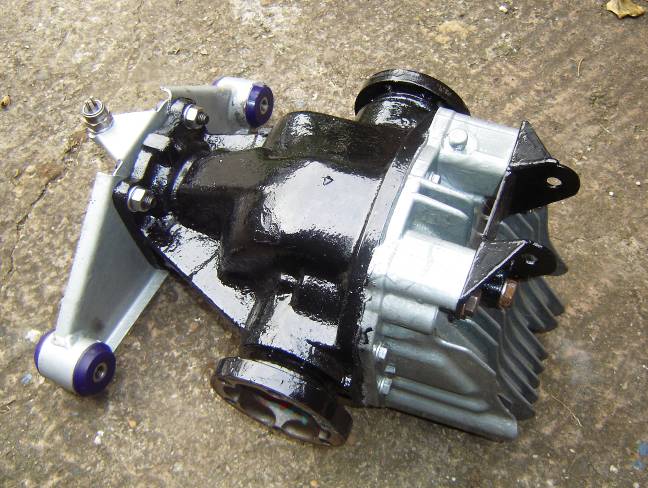

The

diff and box was now back from gearboxman, the result was a hefty bill

because the box needed a whole new gearset due to excessive wear. The

diff was a straight forward rebuild with new bearings. I fitted

new hi-tensile bolts to the diff mount bracket and also changed the old

bushes for nice new purple poly bushes. I gave both of them a

lick of paint with POR 15.

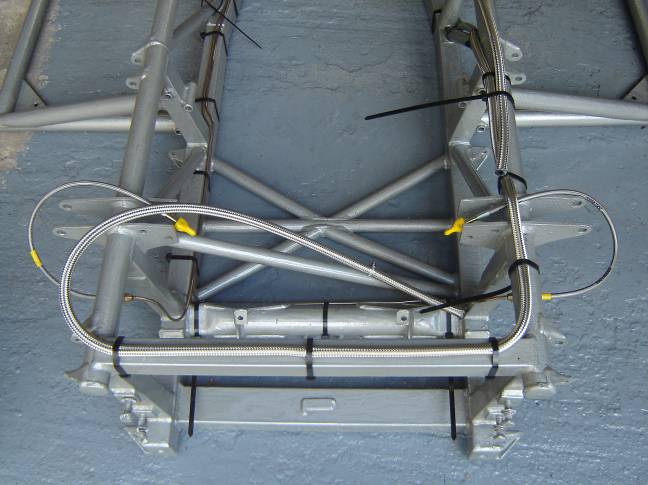

While the chassis was away I polished the brake and fuel lines up! Yes I am that sad!

Brake lines before

Brake

lines after many many hours of polishing, this is a crappy job and I

also did the copper fuel hoses! (All were flushed out before

being re-attached)

For

some reason I didn’t take any photos for a while now, I think I just

wanted to crack on once I’d got the chassis back. I spent a lot

of time removing all the bushes, the best way I found was to heat the

inner part of the bush up with a blow touch and then push this part

out. Then I’d carefully cut two slots in the outer to relive the

tension and then hammer it out. There are a lot of bushes and the

process is very long.

I bought a few metres of

high pressure stainless braided fuel hoses and have used this to

replace all of the rubber stuff (even the low pressure), it should last

far longer. I also bought a set of Goodridge stainless braided

brake lines.

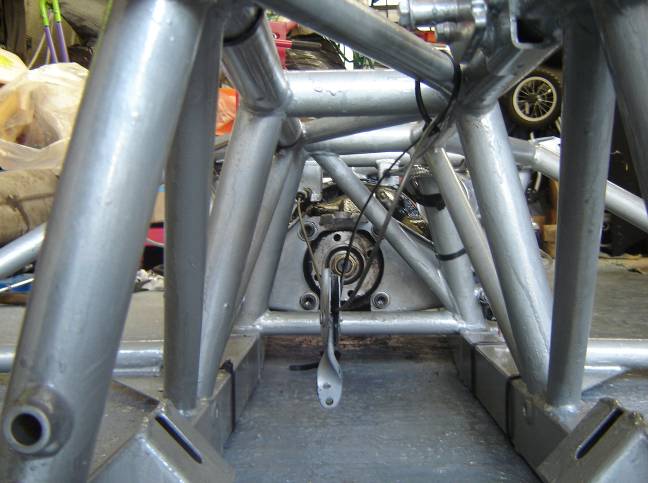

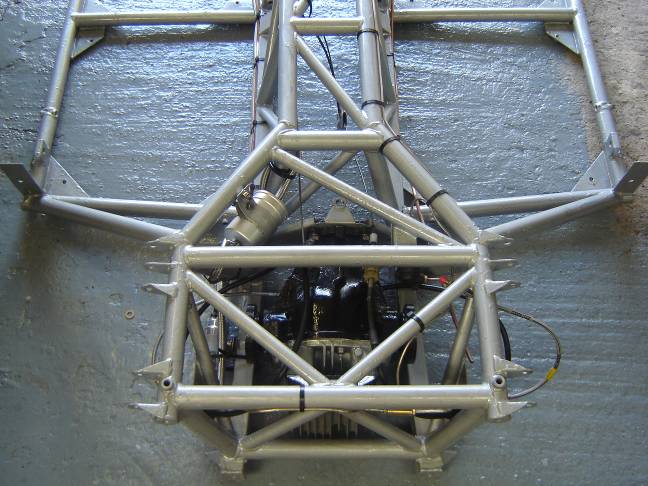

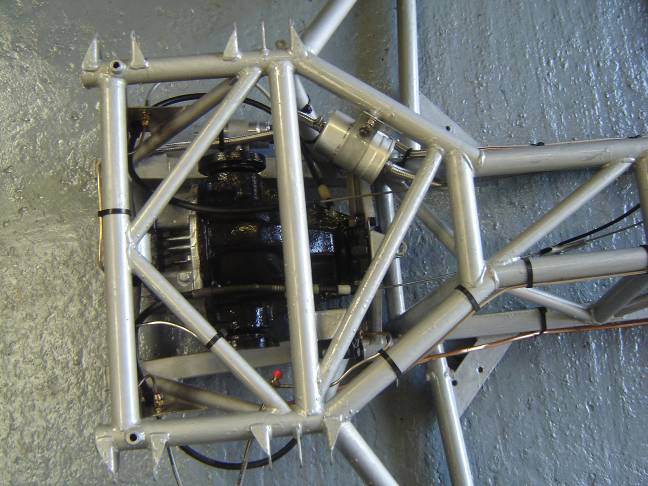

I them prepped the chassis and

wishbones the POR 15 Metal ready whish is a etching acid, this totally

cleans the metal of grease and eats into the surface providing a great

surface for the paint to adhere to. After several coats (must

have been nearly ten on the out riggers!) of silver POR 15 here’s what

the chassis looked like once the diff was fitted. A vast

improvement I’m sure you’ll agree!

Fitting

the diff bushes was great fun! (nearly as much as removing the old

ones) I discovered that they needed trimming down a little.

Here’s the bush before trimming

And here it is again after I’d turned some material off (put it in my drill and used a chisel on it!)

The

underside of the body and the wheel arches were not looking great and

needed a good clean. Scrubbing the under side of the body was a

horrible job and took several hours (over a few days) with white

spirits, rags and brushes. But once it was done I topped it with

a coat of wax to protect it and make it easier to clean in the

future. I painted the wheel arches in a special stone chip

resistant paint and topped it with black POR 15.

It

was time now to fit the new wishbone bushes, I decided to go for the

harder compound Red poly bushes from Superflex, this should help make

the chassis a little sharper (certainly can’t be worse than the ones I

removed anyway!).

After

fitting the wishbones (using new nuts) it was time to mate the chassis

back with the body. I layed cardboard on the floor under the body

and dragged the chassis under and in to place. With the aid of a

few jacks and friend we got the chassis back in to the body. This

was a milestone for me J To see your pride and joy in so many

pieces can be quite worrying, now the major items were back together I

was much happier J

While

the chassis was away being blasted I removed the heat shields from the

engine bay, they were well past their best by now anyway.

Now

that all the bushes had been changed I decided it would be a half job

to put the original dampers back on, they were the original items and

at 10 years old were probably not performing as well as the day they

left the factory.

Choosing

a damper to suit my needs took a while. I asked around after

other peoples experiences with certain dampers and suppliers and

eventually came to conclusion to use the latest generation of GAZ

dampers. I went for the nickel coated option on the damper, 275lb

rear springs and 325lb front springs. I may have to change the

springs at a later date to suit the type of driving I do but I thought

this to be a good starting point. I purchased the springs and

dampers from Derek at absolutely Shocks. Recent reports from

people suggest the dampers are very good; I can’t wait to find out J

My

next step was to re new all the brake disc/pads and buy new

tyres. But I’d always fancied a set of spider wheels in

Anthracite, so I set about researching how to approach the task of

converting my 4 stud hubs to 5 stud and at the same time bought a set

of silver 16inch spiders with the intention of having them powder

coated Anthracite

The

Spiders were second hand but in great condition. But after

weighing up the cost and hassle of having the wheels coated, hubs

converted and buying new disc/pads and tyres all around I decided it

was not for me. So I splashed out on a Spider conversion from the

factory J They came with everything I needed:

Anthracite wheels

5 Stud hubs

Rear discs

New brake line (which I have still not used because I already fitted new Goodridge items)

Big discs (I have now painted the unswept area and inner centre part to prevent corrosion, but I don’t have a pic of it)

4 Pot AP Racing callipers

AP pads all around

Here a pic showing the new 5 stud hub fitted with calliper adaptor bracket awaiting fitment of the calliper

And here with the disc and calliper fitted

And here it was with the wheel on

New

bottom ball joints, track rod ends and top ball joint have been put on

the front. The steering should feel better than new after all

this work J

I then proceeded to clean all of the parts that were going to be going back on the car:

Header tank before

Header tank after a few hours polishing

Steering rack before

Steering

rack after cleaning and polish and refitting to chassis (not the best

pic, it had got a bit dirty by now and needs a wipe down)

Alternator before

Alternator after (fan and pulley powder coated, body polished, blue paint was awaiting a second coat in this picture)

Plenum and throttle linkage before

Plenum and throttle linkage after

Linkage powder coated

Plenum after a lot of polishing

Rocker cover before

Rocker cover after polishing

After

polishing the rocker covers I wasn’t happy with the finish so I sent

them away to be powder coated, I am much happier with this finish

I then prepped a few parts ready for chroming but decided to have them powder coated as well

(Before)

(After)

And a few more bits polished

Wiper motor casing machine polished

I also bought a few bits from ACT J

As

well as the bits above I also purchased a stainless exhaust system from

Tim at ACT, I specced it to look totally standard but be completely

straight through. Basically the same as having the silencer

sleeved but instead of being sleeved it was made that way by JP. I

needed a new exhaust (well would have soon looking at the state of the

old system) anyway so this is why I went this route. My old

silencer was already sleeved.

Me being me I wasn’t happy with how shiny the exhaust was so I set at polishing it up further

The

radiator and fans were looking a bit tired so I cleaned up and

resprayed the rad and spent a lot of time cleaning the fans up

To

finish them off I polished up the aluminium fan holders and spacers and

used stainless stain cap head bolts to attach them (this is an area

that is hardly seen in the car but I still had to do it!)

Distributor with new cap and rotor arm

I

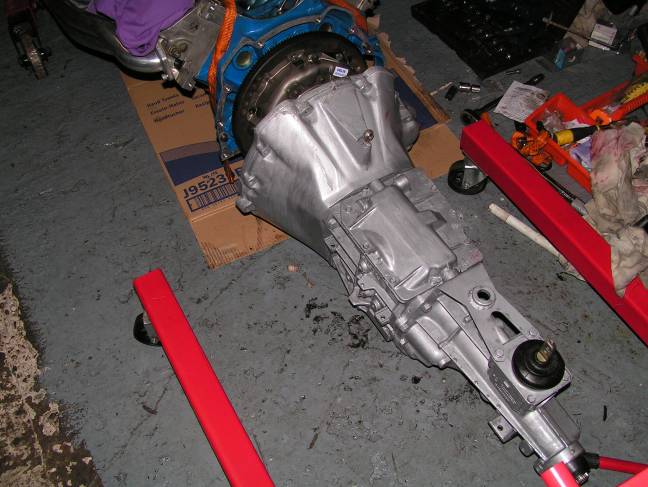

painted the rebuilt gearbox in silver and topped it with POR 15

Glistern clear lacquer; this should provide a durable and easy to wash

finish

I fitted a complete new release arm and bearing assembly

Here’s one of the same shot before the rebuild

Bottom pulley assembled with powder coated parts

It

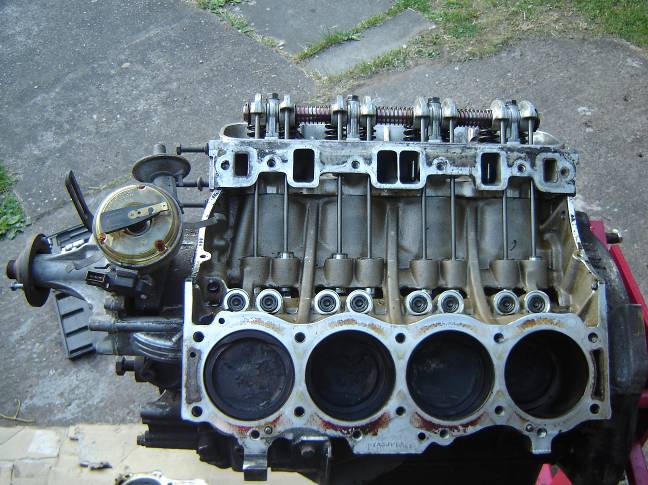

was now time to start the engine strip and see what I was dealing

with. The engine was strong before removal without any poor

running problems, and with only a very slight tap from one of the

tappets when the engine was on over run after the throttle was blipped

and this noise only occurred when the oil was very warm. Why

rebuild then I hear you ask? Well the engine was out already

sooo…..

Removal of the rocker covers didn’t turn up any surprises

Removal of the heads and valley gasket also turned up no problems

The

coke on the piston tops was lifting off; probably due to the amount of

time the engine was left standing before the strip commenced

The cam didn’t show any obvious signs of wear after 40000miles

Combustion chambers turned up no surprises

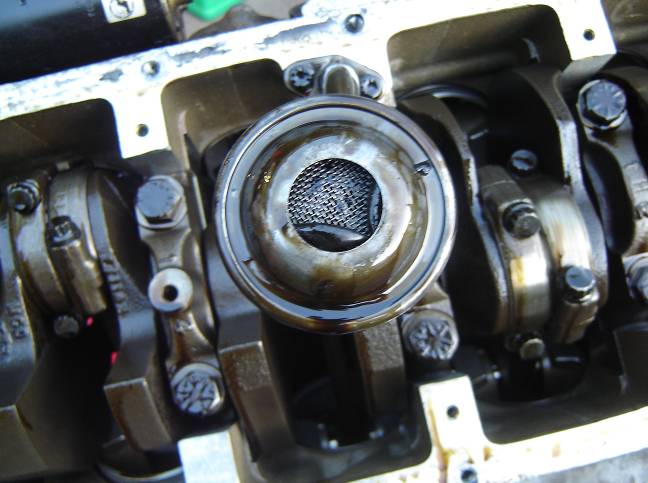

The

oil strainer had a fair bit of sealant in it, probably due to over

zealous use of the sump sealant. Fortunately this had no adverse

affect of the oil pressure

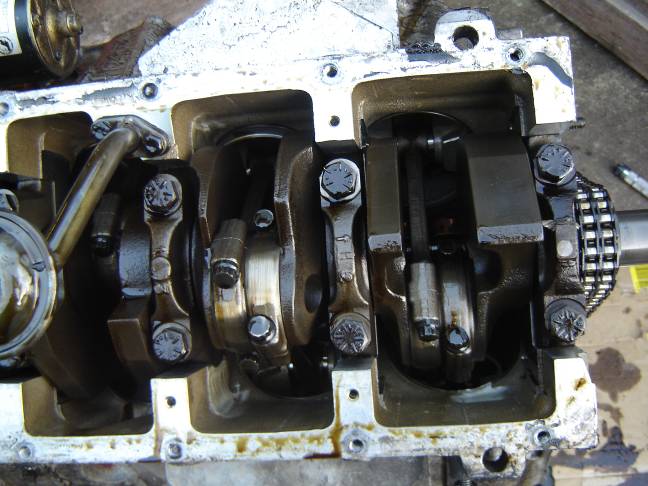

The

valley and the bottom end were looking quite clean, indicating regular

oil changes (backed up by service history), which is good news.

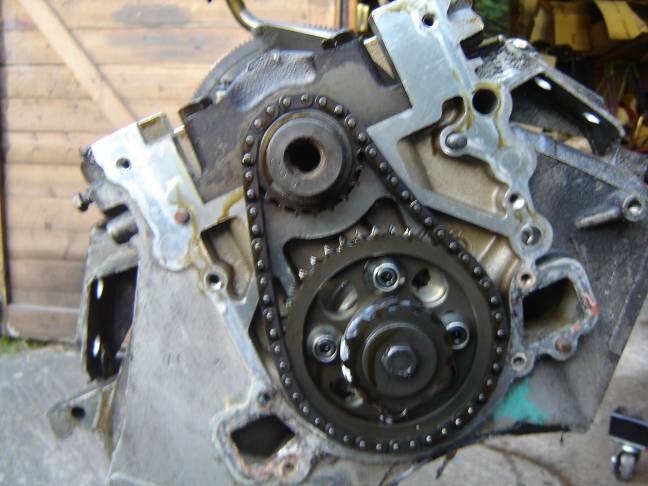

A bit of slack in the timing chain (annoyingly blurry though)

And wear on the teeth

Ta daaa, one stripped engine!

I

cleaned the block up myself to start with; I did this with white

spirits, paint brushes and a jet washer. When I’d finished

washing it I poured hot water over the block to make the water

evaporate faster. I then droves all the excess moisture out with

an oil spray

I

then took the block along to my local machine shop for them to fit the

new cam bearings, hone the cylinder bores, and fit new core

plugs. After the machine work they chemically washed the block

I bought my engine rebuild parts from V8 Developments, I ordered the following items:

Full engine gasket set

H404 camshaft kit (includes cam, vernier timing gear, hydraulic cam followers, valve springs)

Big end and main bearings

Core plugs

Cam bearings

Piston rings

High torque clutch

Oil pump gears

Head bolts

Pushrods

The

cam choice was the only difficult decision during the engine rebuild, I

knew the H404 was as wild as I’d ever want to go but would it be too

wild. That I’d have to find out!!

I polished the pistons up and fitted the new rings to them

I then fitted the new big end bearings, the old ones were not bad but obviously showed signs of wear

To

ensure the bottom end stays together (touches wood) I bought a set of

ARP big end, main bolts and flywheel bolts, I also bought ARP stainless

manifold bolts to go with them.

Unfortunately the big end bolts were not the correct type, so I went to TVR power for some new original items.

Once the block was back I painted it and started to assemble it

I

spent a weekend working on the cylinder heads, I cleaned them up then

decoked the valves. I also reshaped the valves a la Vizzard J and

the ground them in nicely. Then the new valve springs were

fitted. This took quite some time but it’s a job I find it quite

enjoyable J

The pre-cat on the one side was

totally loose in the manifold, I already intended to remove them but

this made sure I was going to have to do it. The loose one came

out without too much trouble but the other one was fixed in solidly,

this took quite a bit of persuasion to remove!

The

removal of the pre-cat won’t make a massive difference; it will mostly

be a noise thing. But what it will do is prevent them getting

blocked up and losing me power.

I sent the

manifold and Y piece away to Camcoat. They cleaned them up and coated

the manifolds internally with their highest spec (black) ceramic

coating; they then coated the manifold and the Y piece externally with

their ceramachrome coating. This looks great I sure you’ll agree

and hopefully will help reduce under bonnet temps

(Inlet manifold only resting in place in this photo)

Due to various horror stories about the standard aluminium rocker I decided to change them for a set of steel ones.

Before fitting the new rockers I timed in the cam on the new timing gear (timing wheel missing on this pic)

With the newly painted front cover on

After

the sump was fitted the engine was now nearly finished so it was time

to fit the new clutch. First the flywheel needed de-glazing then

clutch was aligned and torqued up.

The gearbox was then mated to the engine

While

the engine was out I got hold of some heat resistant aluminium matting

and made some new engine bay heat shields. The new rivets are

stainless so won’t go rusty like the old ones

Looking a little better now than they did before!

Due

to working away and not being able to use my car regular a lot of

strain was put on the battery. I used to jump start the car every

two weeks when I was back home. This killed the battery, which

was not much cop anyway to be honest. So I decided to replace

it. Due to the nature of the engine (large capacity, relatively

high compression) it can take quite a lot of amps to crank it over

strongly. I spent a lot of time researching what would be the

best battery I could fit in the standard position.

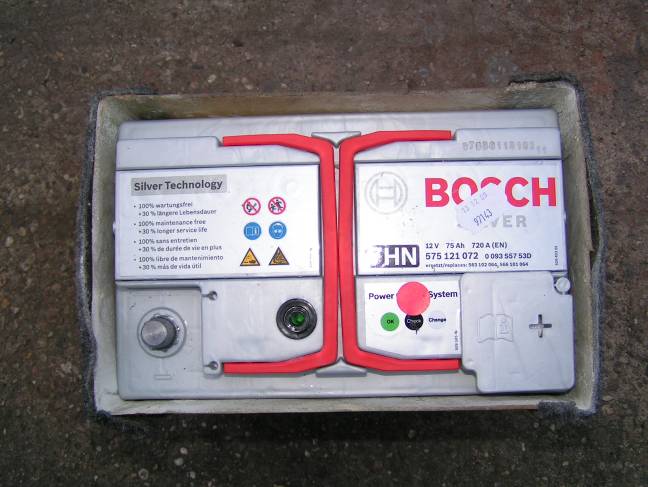

The

conclusion I (finally) came to was a 096 type Bosch Silver Star, these

batteries are supposed to be superb. The cold cranking amps on

this battery are 720amps! And it also puts out 75Ah as a bonus

(not that it’s needed on this car) The CCA sold it to me.

I

bought the battery from my local GSF (German Swedish French car parts)

for £55 after using a 10% discount card (from another car club).

To

fit the battery in to the standard box required the extra feet at the

side of the battery to be cut off (this is really easy being plastic)

and a bit of filing of the corners of the battery box. The

terminal are also the opposite way to standard, this is not a problem

on my car because the leads are long enough to reach. If it was a

problem I would have simply mounted the battery the other way around,

it is no trouble at all reaching over the battery to connect it.

I

have now tested the battery and found that it cranks VERY strongly, and

I have yet to add the Mod wise hot start kit I have bought for it!

It

was now time to add a few more bits to the engine, clean the wiring

loom up and drop the engine back in to the chassis. Actually

manoeuvring the engine and box in to the chassis was not too hard but

mating up the gear linkage and the engine mounts was a real pain.

It should not be too difficult but for some reason it was, you win some

you lose some L

The

next step was to fit the propshaft (cleaned and greased) install the

exhaust. This took a while; the rear mount on the exhaust was no

where near where it should have been so I had to fabricate an adaptor

for it.

The gearbox was then filled with Silkolene fully synthetic after getting advice from an oil expert.

After

adding a few more shiny bits to the engine it was really starting to

come together and I was starting to see the finish line J

And now complete as per when I ran it up

The

engine started second attempt after swinging the dizzy a few

degrees. It sounds bloody marvellous J it’s a great feeling

having completely built this beast with my own hands J

The

idle is a little lumpy due to the cam but I haven’t had chance to drive

it yet to find out have bad it is. I will be in need of a remap

shortly which will help smooth the low speed running a little.

I’m

looking to go to fully mappable fuel and ignition in the near future, I

have built a Megasquirt ECU ready to go on to another car of mine and I

think I may take this route with this car as well.

I have also changed the dashboard for a Leven stainless item (along with all the other bit you have to but when you do this)

Whilst

doing the dash I wet and dried all of the black paint off the dial

surround, the now low massively better and more modern than before.

Dashboard before

Sorry about the dreadful picture (updating soon, it looks a lot better in real life)

Also notice the column cowl in the above picture has a flocked (I said flocked J ) finish now

Flocked cowl

Kontaktaufnahme mit dem Autor und weitere Informationen über info@acs-pro.de

|